The corruption of latex paint in cans is a tricky busin […]

The corruption of latex paint in cans is a tricky business for coatings companies. In the case of commercially available latex paints, it often happens that distributors lose confidence in the product, interrupt sales or make claims. After coating companies "recall" corrupt latex paint, they usually adopt scrap treatment. Improper handling will also pollute water sources and the environment. How to prevent mold and corrosion on latex paint, and how to scientifically treat the latex paint after corruption? This is the issue we will discuss this time ~

Causes of plastic paint corruption:

Under normal circumstances, latex paints that have been properly added with mold and preservatives will not produce mold and corruption. So, why do some paint companies have the deterioration of latex paint? There is only one explanation, that is, under the influence of certain special conditions, the dosage of antifungal and antiseptic is difficult to completely inhibit the growth of mold and bacteria. Or its sterilization speed is slower than the speed of mold and bacteria reproduction.

The phenomenon of latex paint after corruption

The decay of latex paint is caused by the action of mold or rot fungi (bacteria) separately or together. So what will happen after the latex paint is corrupted?

Phenomenon after latex paint corruption

corruption

Mildew and corruption.

That is, by the combined action of rot fungi and mold, the latex paint has a strong odor, accompanied by blackening, precipitation, flocculation, and agglomeration.

Environmental impact

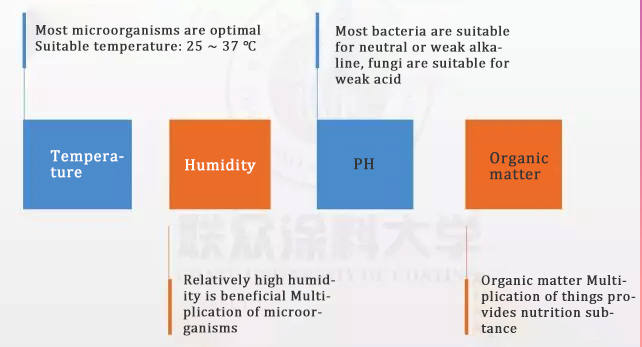

There are five conditions that determine the survival and reproduction of mold and rot fungi (bacteria), namely temperature, moisture, oxygen, bacteria species, and pH. These five conditions are closely related to the environment.

Influence of temperature

As far as the influence of temperature on the reproduction of mold and rot fungi (bacteria) is concerned, 25 to 35 ° C is most suitable for the reproduction of molds; above 35 ° C is most suitable for the reproduction of rots. Latex paint is not easy to deteriorate when the temperature is low. The reason is here. Therefore, in high temperature seasons, it is easy to cause mold or corruption of latex paint.

Effect of moisture

The reproduction of rot fungi and mold requires water. The moisture content in the air is expressed by humidity. The humidity is high, and it is easy to multiply rot and bacteria. Latex paint in the south is more susceptible to deterioration than the north, because the humidity in the south is higher than in the north. Under high humidity conditions, molds and bacteria are prone to be present on production equipment, packaging containers, and workshop walls. Latex paint produced under these conditions is prone to deterioration.

oxygen

Latex paints are not easy to deteriorate in places with high altitude and low oxygen content, while latex paints are easy to deteriorate in areas with low altitude and high oxygen content. Latex paints in plain areas and water net areas are often prone to deterioration.

Strain

The production process of latex paint is a fungal operation, that is, the finished paint basically contains a variety of bacterial species, and it begins to breed when it meets the appropriate conditions.

PH

Generally speaking, latex paints with lower pH are more likely to deteriorate than latex paints with higher pH. Because bacteria are prone to degenerate acidic materials, the process of decay and deterioration of latex paint is the process of its conversion from alkaline to acidic. Therefore, the process of deterioration of latex paint is also called "rancidity".

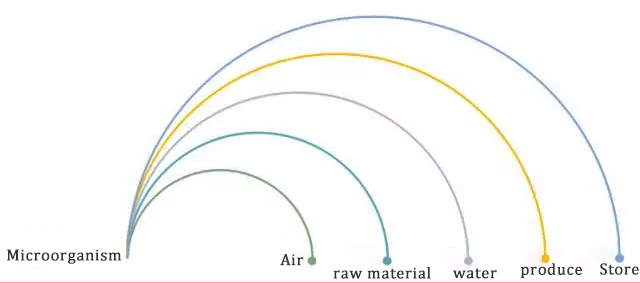

Influence of raw materials

The raw materials for latex paints contain a variety of bacteria, and some raw materials may be moldy and rotten before use, which exacerbates the moldy and rottenness of latex paints.

Influence of powder

The fillers and colored pigments for latex paints contain bacteria on their surfaces, and pigments with a larger specific surface area will have more bacteria. In particular, superfine fillers and fillers with small specific gravity have a large amount of bacteria on the surface and in the capillaries. When encountering a suitable environment for bacteria, its reproduction speed will be greatly accelerated, and the emulsion paint produced therefrom will contain a large amount of bacteria.

Effect of additives

It is certain that bacteria are present in the additives. Cellulose degradation, mold, loss of viscosity; dispersants, wetting agents, defoamers and other auxiliary agents viscosity reduction, discoloration, odor, can be understood as spoilage. In daily production, we pay more attention to the deterioration of cellulose products and ignore the possibility of deterioration of other additives, which brings difficulties to deterioration analysis. One paint company found that latex paint was corrupt and deteriorated in the summer. After several tests of elimination, it was finally discovered that the problem was with the dispersant. The dispersant deteriorates. First, the pigment is flocculated and precipitated. The bacteria in the dispersant multiply in the latex paint and cause the latex paint to odor and blacken, resulting in great loss.

Effect of emulsion

Although the production of the emulsion is carried out at a relatively high temperature, the packaging of the product with bacteria in the air is sure to carry the bacteria. Some emulsion manufacturers believe that emulsions are produced at sterilization temperature without bacteria, so they hurriedly leave the factory without adding any bactericide, which brings great difficulties to the product quality control of coating companies.

How to prevent the latex paint from suffering and spoiling?

Once you understand the cause of latex lacquer spoilage, it's easy to find ways to prevent it.

The production workshop should be spacious, bright, ventilated and ventilated. During the rainy season, the humidity of the workshop should be minimized, and cleaning is often done. In a word: minimize the living conditions of bacteria and suppress the reproduction rate of bacteria as much as possible.

Raw materials must be strictly inspected and accepted. It is particularly important that production workers must be careful and careful when they feed, accumulate rich production experience, and intuitively identify whether the quality of raw materials has changed during storage, and report abnormalities immediately.

3.Production Process.

In order to make the mold and preservative produce the largest bacteriostatic and bactericidal effect. It should be added early in the formulation to ensure that it is evenly dispersed in the latex paint. In regions and seasons with high temperature and high humidity, increase the amount of mildew and preservatives appropriately. In high-temperature and high-humidity regions and seasons, after the end of daily production, clean the parts that are in contact with the air, such as containers, equipment, and pipes. In order to prevent molds and bacteria from multiplying on the inner walls of pipes and equipment, especially for equipment and pipes that have not been used for a long time, more attention must be paid.

Scientific treatment of moldy and rotten latex paint

So, how do we deal with the moldy and rotten latex paint?

Mildew

Mildew generally occurs at the interface between the latex paint and the air layer, local mold spots or mildew spots are generated on the surface of the latex paint, and the internal appearance of the latex paint does not change. In this case, after sampling inspection, under the condition of constant performance, generally open the can to remove the mold spots or mold spots on the surface of the latex paint, and then pour it into the paint mixing tank while stirring to add the diluted Antifungal agent, stir at 500 ~ 700 r / min for 30 minutes and then repack. If the cans show large mold spots on the surface of the latex paint, if you carry out pre-treatment as mentioned above, you must add a small amount Emulsion and related additives.

Stirring test

The spoiled latex paint is sampled after stirring at moderate speed. Detect the degree of demulsification after the action of bacteria on the emulsion by testing. Generally speaking, the performance of interior wall latex paints does not change much, and the exterior wall latex paints can maintain strong anti-aging properties (by 4 years of natural exposure contrast test).

Additives

(1) Add mold and preservatives.

Add mold and preservatives at a ratio of 1: 1000 or 1.5: 1000. First of all, this anti-mildew and preservative must have deodorizing function, because users will never approve latex paint with strong odor. Moreover, it must have a good bactericidal function, and then the bacteriostatic function is considered. The choice of anti-mildew and antiseptic must also have gas and liquid sterilization functions. Because the mold is produced at the gas-liquid (latex paint) phase interface, and the rot is produced in the liquid (latex paint). At the same time, the anti-mildew and anti-corrosive fungicide with gas and liquid sterilization function can simultaneously kill the mold and rot fungi in the gas and liquid phase.

(2) Add dispersant, wetting agent and defoamer.

Severe water separation, flocculation, and bottoming appear in rotten latex paints. The reason is that the dispersant, wetting agent, and defoamer have been partially or completely ineffective due to bacterial attack. Therefore, it is necessary to add dispersant, For aerosols and defoamers, the original dosage is 1: 2.

(3) Add a pH adjuster.

After mildew and decay of the latex paint, the continuous reproduction of bacteria causes the latex paint to gradually change from weakly alkaline to acidic. In order to restore the thickening effect of the thickener in the alkaline state, a pH adjuster must be added to adjust the pH to 8 -9 is better.

Add emulsion

After the latex paint is corrupted, some of the emulsion must be demulsified and rancid. Therefore, it is necessary to add an emulsion. The amount of the additional emulsion is preferably 10% to 15% of the emulsion in the original formula.

Add thickener

After the emulsion is added, the viscosity must be readjusted. In the process of readjusting the viscosity, an associative thickener and an alkali swelling thickener may be mixed for use. The viscosity adjustment of exterior wall emulsion paint is mainly associative thickener, and the viscosity adjustment of interior wall emulsion paint is mainly alkali swelling thickener. Because the associative thickener obviously thickens the emulsion, and the alkali swelling thickener thickens the system obviously.

The storage time of the latex paint after treatment can generally be maintained for one year. The anti-mildew and anti-corrosion of the latex paint is an important part of the production process. At present, a few paint factories use tap water, deep well water or river water as the diluent directly. Although this production reduces the cost, it increases the possibility of latex paint mildew and corruption. It is recommended to use pure water as the diluent.